T2150 Special Deephole Drilling Boring Machine bakeng sa Energy Wind Spindle Motor

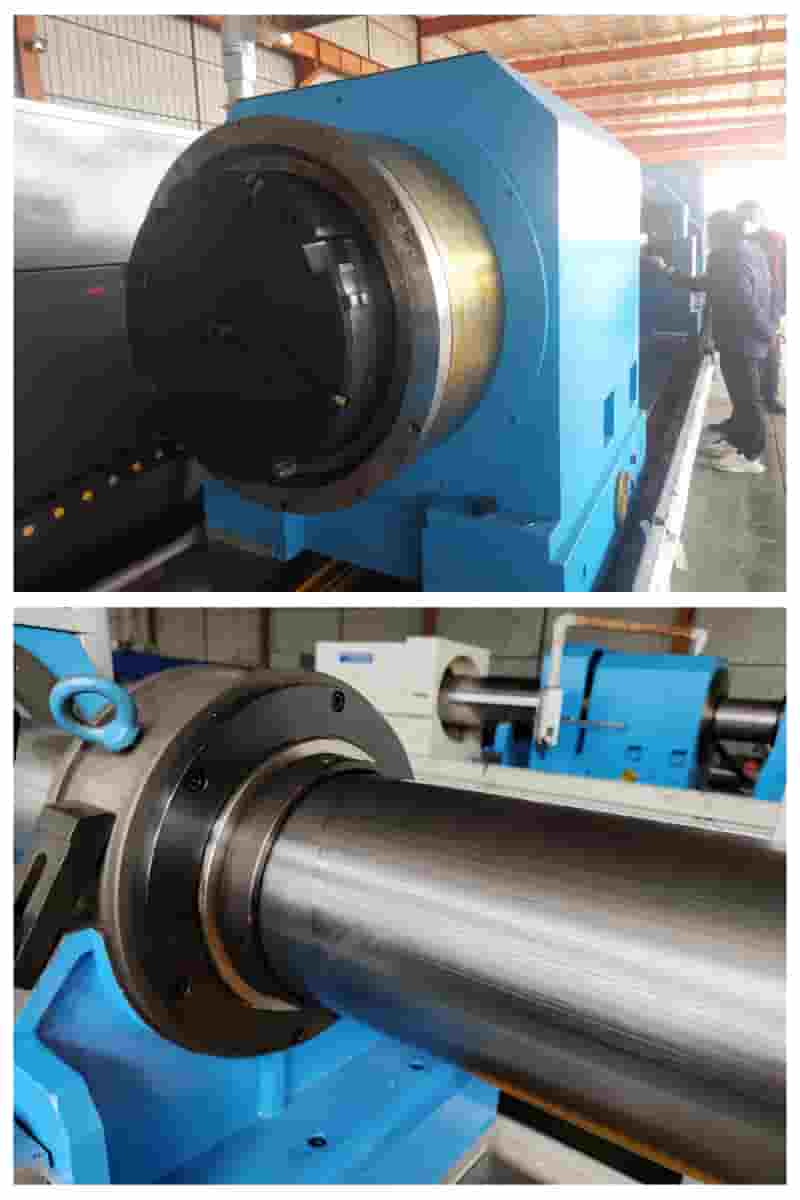

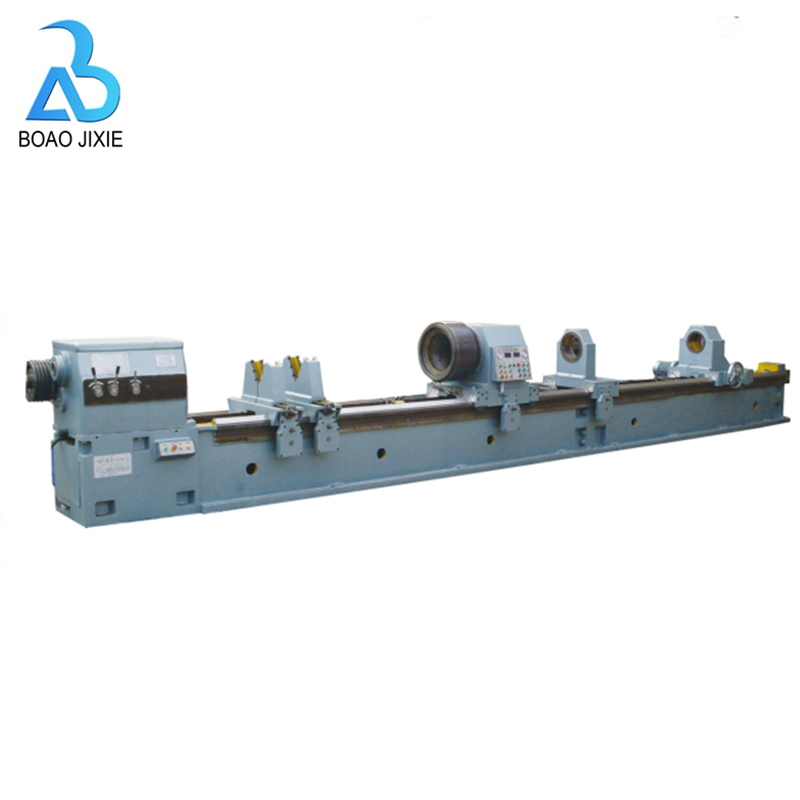

Sebopeho sa Mochini

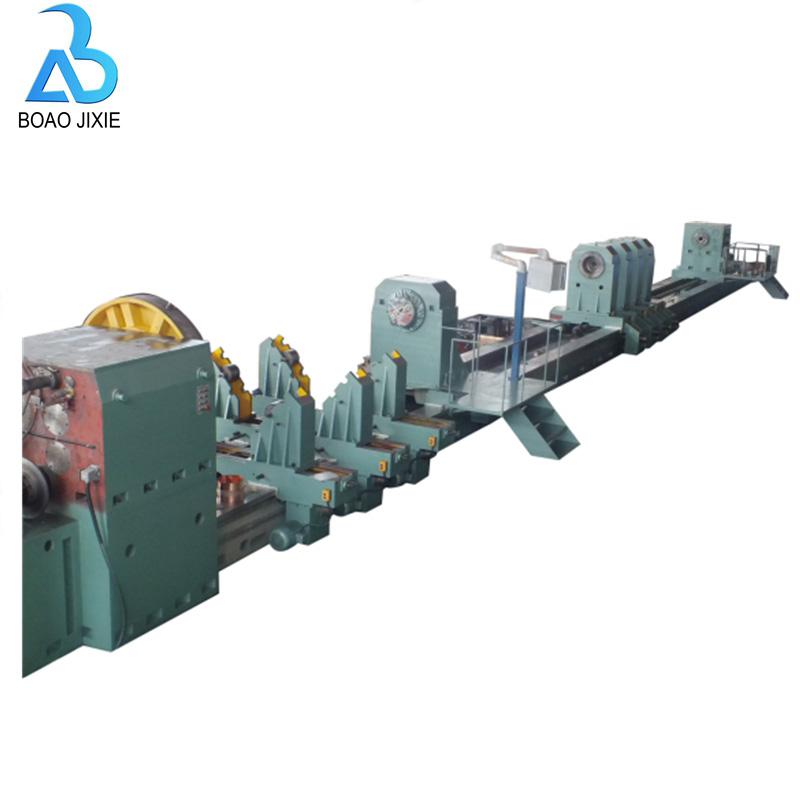

T2150 ho phunya lesoba le mochini o borata ke sesebelisoa sa mochini o tebileng oa lesoba se entsoeng ke k'hamphani ea rona ho latela litšobotsi tsa ts'ebetso ea lisebelisoa tsa hona joale tsa spindle tsa matla a moea le litlhoko tsa mmaraka.Sesebelisoa sa mochini ka boeona se na le ho tiea ho matla mme se boloka ho nepahala hantle.Spindle e nka taolo ea lebelo la lebelo le sa tsitsang ka lebelo le holimo, le se nang letho, le tlase), 'me lebelo le pharaletseng.Sistimi ea phepelo e tsamaisoa ke enjene ea matla e phahameng ea AC servo, e ka fihlelang litlhoko tsa lits'ebetso tse fapaneng tsa ho lokisa mekoti e tebileng..Oiler e sebelisoa ho tiisa workpiece ka mochine oa mochine, o sireletsehileng le o ka tšeptjoang.Sesebelisoa sa mochini se ka phethela ts'ebetso ea ho phunya, ho bora, ho holisa le ho roala ha likarolo tse tebileng tsa lesoba le bophara bo boholo.Nakong ea ts'ebetso, workpiece e potoloha ka lebelo le tlaase, 'me sesebelisoa se potoloha le ho fepa ka lebelo le phahameng.Ha u cheka, sebelisa mokhoa oa theknoloji oa ho tlosa chip ho BTA;ha o bora, sebelisa mokhoa oa thekenoloji oa ho fana ka mokelikeli oa ho itšeha ka har'a bareng e tenang le ho ntša mokelikeli oa ho itšeha le litšepe ho ea pele (hloohong ea hlooho);ho latela litlhoko tsa ts'ebetso, sesebelisoa sa mochini se na le lebokose la drill Rod, sesebelisoa se ka potoloha le ho feptjoa.Sesebelisoa sa mochini haholo se kenyelletsa bethe, lebokose la hlooho ea bethe, lebokose la liphaephe tsa ho cheka, phepelo ea oli, sistimi ea phepelo, foreimi ea setsi sa mosebetsi, bracket ea workpiece, tšehetso ea bar, koloi ea phepelo, sistimi e pholileng (ka sesebelisoa sa ho tlosa chip), sistimi ea hydraulic.Sesebelisoa sena sa mochini se ka khetha ka mokhoa o bonolo mokhoa oa ho sebetsa ho latela litlhoko tsa 'nete,' me se na le mefuta e mengata ea likopo.

| NO | Lintho | Tlhaloso |

| 1 | Letoto la mohlala oa mochini | T2150 |

| 2 | Bophahamo ba ho phunya bo letse | Φ30-120 limilimithara |

| 3 | Boring bophara bo ile ba lla | Φ220-500mm |

| 4 | Botebo ba ho tena | 1-12m |

| 5 | Fixture clamping range | Φ1600 limilimithara |

| 6 | Bophahamo ba setsi sa mochini oa spindle | 900 limilimithara |

| 7 | Headstock spindle lebelo | 1-225 r/m , 3 gearless, stepless |

| 8 | Bophara ba lesoba la spindle | Φ130 limilimithara |

| 9 | bophara ba lesoba la sepindle ka pele | 140 # |

| 10 | Boring bar box spindle lesoba bophara | Φ120 |

| 11 | Boring bar box spindle ka pele ho lesoba la taper | 140#, 1:20 |

| 12 | Boring bar box spindle lebelo | 20-400 rpm, makhasi a 6 |

| 13 | Pallet e tsamaeang ka lebelo le potlakileng | 2m/mots |

| 14 | Lebelo la ho fepa | 5-1000mm / min, e se nang mohato |

| 15 | Enjene ea mantlha | 45 kw |

| 16 | Boring bar motor | 22KW |

| 17 | Fepa matla a motlakase | 1.5kw |

| 18 | Ho fepa koloi ka potlako matla a motlakase | 5.5KW |

| 19 | Enjene ea pompo e pholileng | N=5.5kw (lihlopha tse 3) |

| 20 | Khatello e lekantsoeng ea sistimi e pholileng | 2.5Mpa |

| 21 | Ho phalla ha tsamaiso ea ho pholisa | 100, 200, 500 L / min |

| 22 | Sisteme e futhumatsang e lekantsoe khatello | 6.3 Mpa |

| 23 | Boholo ba matla a axis force | 6.3 Kn |

| 24 | Matla a ho lokisa oiler bakeng sa workpiece | 20KN |

| 25 | Boima ba boima bo phahameng mochining | 20T |

| 26 | Tsamaiso ea taolo | Siemens 808 kapa KND |

Likarolo tsa bohlokoa tsa Mochini