Mofuta oa ZT Casing Drilling bit, Reaming Hlooho e Boring

Tlhaloso ea Sehlahisoa

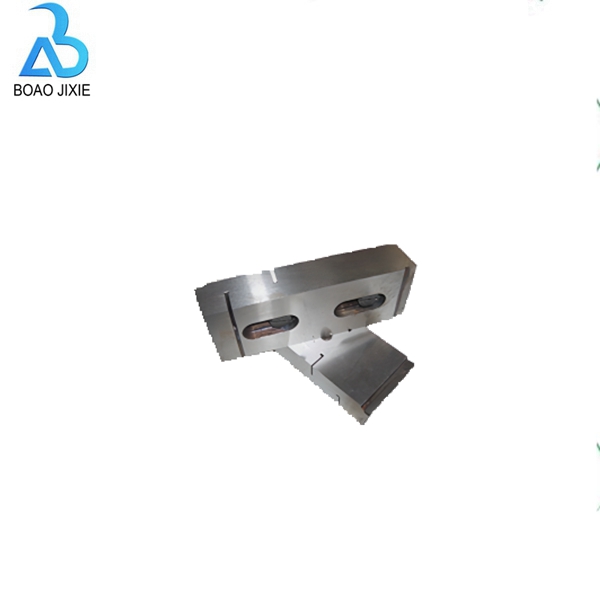

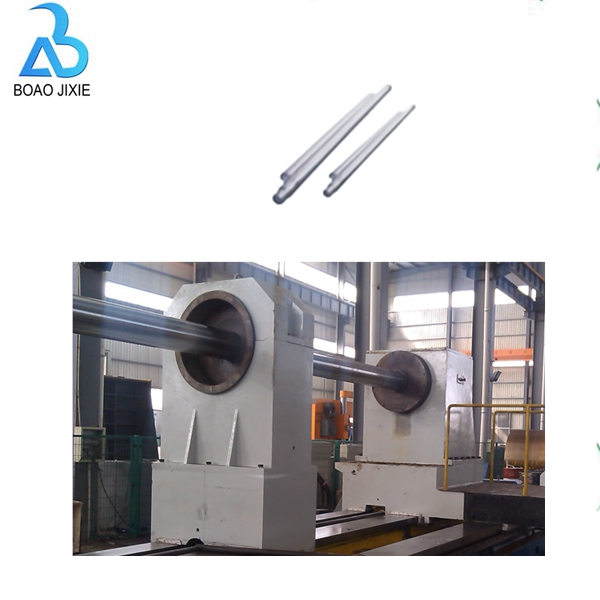

Casing Drilling bit e boetse e bitsoa annular drill, ke sesebelisoa sa moruo, se hlahisang le sa boleng bo holimo.Ho molemo ho sebelisa sekoahelo sa ho phunya ha casing bakeng sa ho lokisa lesoba le ka holimo ho 50mm ka bophara. Sesebelisoa sena se sebetsa maemong a latelang:

(1) Bophara ba lesoba ke 50mm ka holimo, 'me ka mamello e haufi ea ho otloloha le ho nepahala ha boemo

(2) Karo-karolelano ea bolelele-ho-diameter ea sekoti e sebakeng sa 1 ~ 75, ke khetho e ntle ea ho sebelisa hlooho ea casing drilling bit ho feta mekhoa e meng ea machining.

(3) Thepa ea mosebetsi e theko e boima haholo 'me motheo o hloka ho lekanya le tlhahlobo ea lik'hemik'hale,' me mandrel eohle ea mantlha e hloka ho bolokoa.

(4) Matla a mochini ha a lekana ha o phunya lesoba le leholo, ka hona, trepanning ke khetho e ntle.E loketse bophara ba ho tloha ho 50 ho isa ho 600mm (bara ea lisebelisoa tse tšoanang le eona e lokela ho romelloa).

| NO. | Mathata | Lebaka | Tharollo |

| 1 | Chip ea mochini e nyane haholo | data e fosahetseng ya ho seha

| Fetola Lebelo le Phepo |

| Geometry e fosahetseng ea chip, ellipse angle e nyane haholo kapa e tebile haholo

| Fetola mefuta e metle ea li-slot | ||

| Ho se tsitse ha thepa ea workpiece | Fetola Lebelo le Phepo | ||

| Sekhahla se fosahetseng sa pele (sesebelisoa ha se tsejoe) | Setsi sa lesoba la boemo | ||

| 2 | Chip ea mochini e kholo haholo | data e fosahetseng ya ho seha | Fetola Lebelo le Phepo |

| Geometry e fosahetseng ea chip, ellipse angle e nyane haholo kapa e tebile haholo | Fetola mefuta e metle ea li-slot | ||

| 3 | Machining chips ha li tšoane | Lisebelisoa tsa workpiece ha li tšoane | Fetola mefuta e metle ea li-slot |

| Mokhoa o fosahetseng oa ho fepa (ho fepa ka hydraulic) | Sheba le moetsi | ||

| Pholiso ha e ntle | Etsa hore pholile e be kholoanyane | ||

| Ho thothomela ho matla ho bakoang ke ho se lekane ho tsitsitseng ha sesebediswa le sesebelisoa Thepa ea workpiece ha e tsitsa. | Sheba le moetsi | ||

| 4 | Lithako tsa tšepe tse nang le fiber | Lisebelisoa tsa workpiece ha li tšoane | Fetola mefuta e metle ea li-slot |

| Mokhoa o fosahetseng oa ho fepa (ho fepa ka hydraulic) | Sheba le moetsi | ||

| Sepholisa se sa lekaneng | Sepholisa se hloekileng | ||

| Karabelo ea kamano ea lik'hemik'hale lipakeng tsa sesebelisoa sa mosebetsi le sesebelisoa sa carbide | phetoho | ||

| ho qhoqhoa ha chip | phetoho | ||

| fepa tlase haholo | Ntlafatsa phepelo | ||

| 5 | Ho chesoa ha li-carbide tse kentsoeng ka samente | Cutter ha e potlake | Fetola |

| Coolant ha e sebetse hantle | Hlahloba phallo le khatello | ||

| Sepholisa se sa lekaneng | Sheba se pholileng | ||

| Mamello ea bushing ea tataiso e nyane haholo | Fetola | ||

| Sebaka sa ho cheka le spindle ke eccentric | Fetolela ho eccentric | ||

| Sekhechana se fosahetseng parameter | Fetola | ||

| Lisebelisoa tsa workpiece ha lia tsitsa | Beha lebelo le nepahetseng le fepa |